Tel: 0417-6996888

Mobile: 13332312177

Contact: Manager Han

Address: Tieling Street Village, Dashiqiao Economic Development Zone, Yingkou

Website: www.china-zkjt.com/en

Development of synthetic mica

Due to the small reserves of natural mica in my country, especially high-quality and large mica, it cannot meet the development needs of the electronics industry. Since the 1950s, domestic research on synthetic mica has begun. In 1963, the Institute of Non-Metallic Minerals of the Ministry of Building Materials used the internal heat method to develop synthetic mica as soon as it was established. For more than 40 years, Sinoma IOL Research Institute has achieved a total of 25 scientific research achievements in the field of research, development, promotion and application of synthetic mica, and has won the second prize of the National Defense Industry Office, and a total of 12 ministerial-level scientific and technological progress awards from the State Economic Commission and the State Science and Technology Commission. item. In terms of growing large-scale synthetic mica crystal technology, my country is at the leading level in the world.

Research and Development Theory of Synthetic Mica

According to crystallographic theory, if the ions have the same valence and similar volumes, they may replace each other. Fluoride ion F- and hydroxyl ion (OH)- have the same electric valence, the ionic radius of F- is about 0.13nm, and the ionic radius of (OH)- is about 0.14nm. can be achieved in. The mica formed by replacing (OH)- with F- is called fluoromica, and F is introduced in the form of fluoride, and the mica obtained by high temperature melting or solid-phase reaction is called synthetic fluoromica, in which fluorophlogopite KMg3 (AlSi3O10 ) F2 is easier to grow into large crystals and has the greatest practical value. Therefore, the commonly referred to as synthetic mica refers to fluorphlogopite.

Since synthetic mica does not contain hydroxyl (OH), its high temperature thermal stability is much higher than that of natural mica, as shown in Figure 1 [1]. Natural muscovite starts to decompose from 450°C, and its thickness expands. It loses weight sharply above 6000°C. When it reaches 900°C, it is almost completely decomposed, and the mica structure is completely destroyed, leaving only some metal oxides and impurities. Phlogopite starts to decompose from 750℃, and the weight loss is remarkable above 900℃. Therefore, their maximum use temperature is: muscovite 550 ℃, phlogopite 800 ℃. Synthetic mica can be used up to 1100°C until it is slowly decomposed (fluoride) when it reaches above 1200°C. The melting temperature of fluorophlogopite is about 1375±5℃. It is easy to distinguish mica types by high temperature heating or differential thermal analysis.

In addition, due to the purity of synthetic mica, less impurities and good transparency, except the hardness is slightly larger than that of natural mica, other mechanical properties, electrical insulation properties and vacuum outgassing properties are better than natural mica. It can be seen that synthetic mica can not only completely replace natural mica, but also a new type of high temperature resistant insulating material with special properties. my country's natural mica reserves are small, especially high-quality, large-scale mica, which cannot meet the development needs of the electronics industry. Since the 1950s, synthetic mica has been studied in China. In 1963, the Institute of Non-Metallic Minerals of the Ministry of Building Materials used the internal heat method to develop synthetic mica as soon as it was established. For more than 40 years, Sinoma IOL Research Institute has achieved a total of 25 scientific research achievements in the field of research, development, promotion and application of synthetic mica, and has won the second prize of the National Defense Industry Office, and a total of 12 ministerial-level scientific and technological progress awards from the State Economic Commission and the State Science and Technology Commission. item. In terms of growing large-scale synthetic mica crystal technology, my country is at the leading level in the world.

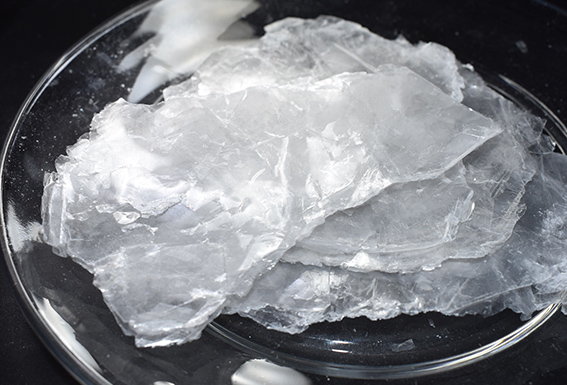

The growth of synthetic mica is by high-temperature melting crystallization method under normal pressure. The main process is: select potassium fluorosilicate, quartz powder, fused magnesia, alumina powder and potassium carbonate as raw materials, and refer to the theoretical composition KMg3(AlSi3O10)F2 , optimize the best formula→weighing→mixing→adding to the internal heat melting furnace made of refractory bricks→electricity melting→clarification→cooling and crystallization→cooling→synthetic mica crystal block→crushing and peeling→finished product, from crystal A small amount of single wafers can be peeled off from the block, and most of them are broken wafers. Through comprehensive utilization, various synthetic mica products can be obtained.